Corten Steel: Essential Guide to Surface Preparation & Coating Systems

Corten steel—also known as weathering steel, can be painted with High Performance Coatings for color or architectural aesthetic design.

- High Performance Coatings

Corten steel is otherwise known as weathering steel, so why would you coat it?

Corten steel: Essential Guide to Surface Preparation and Coating Systems:

What Is Corten Steel and Why Is It Special?

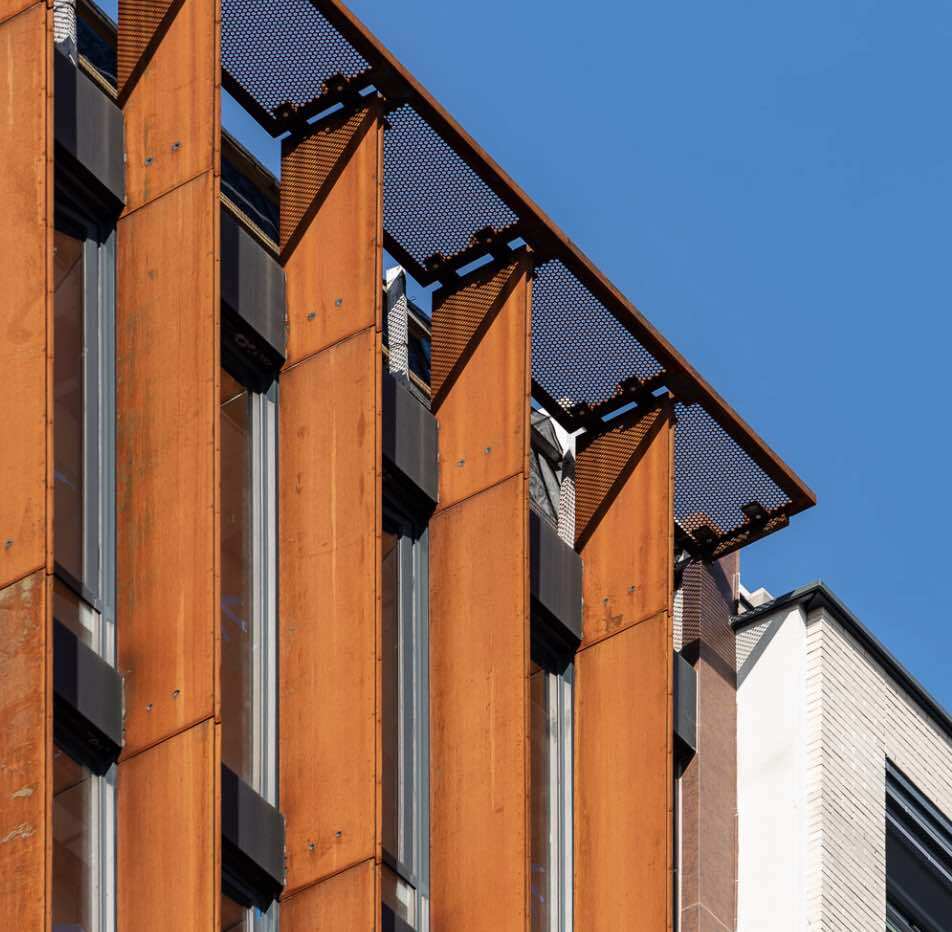

Corten steel—also known as weathering steel—has revolutionized architectural and structural design with its unique combination of durability and aesthetic appeal. Unlike conventional steel, Corten develops a distinctive rust-colored patina that actually protects the material from further corrosion. However, many times owners or specifiers are being asked to paint Corten with High Performance Coatings for color or architectural aesthetic design.

The name "Corten" derives from its two primary characteristics:

- CORrosion resistance

- TENsile strength

This specialized alloy contains carefully balanced amounts of copper, chromium, nickel, and phosphorus. When exposed to the elements, these elements form a stable, tightly-adhered oxide layer that shields the underlying metal while creating the material's signature reddish-brown appearance.

"Corten steel offers the perfect marriage of industrial strength and natural aesthetics, making it a favorite among architects and designers seeking materials that tell a story through their aging process." — Modern Architectural Review

Where You'll Find Corten Steel

The distinctive appearance and corrosion-resistant properties of Corten have made it increasingly popular in:

- Architecture: Façades, decorative panels, and statement features

- Public Art: Outdoor sculptures and installations

- Infrastructure: Bridges, railway cars, and shipping containers

- Landscaping: Planters, retaining walls, and garden features

- Interior Design: Accent walls, furniture, and decorative elements

The Critical Importance of Surface Preparation

Even with its natural corrosion resistance, when applying coatings, Corten steel requires proper surface preparation before coating to ensure maximum performance and longevity. This is particularly important for applications where a controlled appearance is desired or where additional protection is needed.

Industry-Standard Blast Cleaning Methods

The Society for Protective Coatings (SSPC) and National Association of Corrosion Engineers (NACE) define the following standards for surface preparation:

| Standard | Description | Best For |

|---|---|---|

| SSPC-SP6/NACE 3 | Commercial Blast Cleaning | Light-duty environments |

| SSPC-SP10/NACE 2 | Near-White Blast Cleaning | Most exterior applications |

| SSPC-SP5/NACE 1 | White Metal Blast Cleaning | Severe environments |

The Gold Standard: Near-White Blast Cleaning

For most high-performance coating applications on Corten steel, SSPC-SP10/NACE 2 Near-White Blast Cleaning is the recommended minimum standard. This process removes nearly all contaminants, with only slight staining permitted on no more than 5% of each square inch.

The blast cleaning should create an angular profile of 1.5 to 2.5 mils (thousandths of an inch) to provide optimal mechanical adhesion for coatings.

Specialized Coating Systems for Steel

Interior Protection: The Two-Coat System

For interior Corten steel applications, a two-coat system provides excellent protection against chemicals and abrasion while maintaining corrosion resistance:

Base Coat: Tnemec Series 94 (Tneme-Zinc)

This zinc-rich primer forms the foundation of protection through galvanic action. With 83% zinc dust by weight in the dried film, it sacrificially protects the steel substrate—similar to how galvanizing works.

Key Properties:

- Self-healing capabilities for small scratches

- Excellent adhesion to properly prepared steel

- Creates a corrosion-resistant foundation

Topcoat: Tnemec Series 1095 (Endura-Sheild)

This acrylic polyurethane coating completes the interior system with:

Key Properties:

- Outstanding color performance and availability

- Low VOC (LEED approved)

- High-build capabilities for uniform coverage

- Long-term durability in interior environments

Exterior Protection: The Three-Coat System

Exterior applications demand comprehensive protection against UV degradation and weathering. A three-coat system provides the optimal balance of corrosion protection, chemical resistance, and aesthetic durability:

Base Coat: Tnemec Series 94 (Tneme-Zinc)

This zinc-rich primer forms the foundation of protection through galvanic action. With 83% zinc dust by weight in the dried film, it sacrificially protects the steel substrate—similar to how galvanizing works.

Key Properties:

- Self-healing capabilities for small scratches

- Excellent adhesion to properly prepared steel

- Creates a corrosion-resistant foundation

Intermediate Coat: Tnemec Series N69 (Hi-Build Epoxoline II)

This advanced epoxy builds upon the zinc primer with:

Key Properties:

- High-build characteristics for seamless coverage

- Excellent edge retention

- Enhanced chemical resistance

- Strong barrier protection

Finish Coat: Tnemec Series 701 (HydroFlon)

This fluoropolymer topcoat provides the ultimate protection against environmental factors:

Key Properties:

- Exceptional UV resistance

- Outstanding color and gloss retention

- Extreme weatherability (15+ years)

- Resistance to chalking and fading

- Low maintenance requirements

Interior vs. Exterior Systems: Key Differences

| Feature | Interior System | Exterior System |

|---|---|---|

| Number of Coats | 2 (primer + topcoat) | 3 (primer + intermediate + finish) |

| UV Protection | Minimal | Excellent |

| Color/Gloss Retention | Good for interior | Superior, even in harsh sunlight |

| Maintenance Requirements | Low | Very low |

| Relative Cost | More economical | Higher investment |

| Application Time | Faster | Requires additional coat and cure time |

Ensuring Long-Term Success

The combination of proper surface preparation and appropriate coating selection is critical for maximizing the performance of Corten steel. While the material's natural patina provides some protection, engineered coating systems offer enhanced durability and aesthetic control.

For projects requiring the ultimate in protection and appearance, following these best practices will ensure your Corten steel structures maintain their integrity and beauty for decades to come:

- Verify surface preparation meets SSPC-SP10/NACE 2 standards

- Confirm proper profile depth of 1.5 to 2.5 mils

- Apply coatings within specified environmental conditions

- Adhere to recommended dry film thickness for each coat

- Allow proper cure time between coats

- Conduct regular inspections and maintenance as needed

"The relatively higher upfront cost of proper surface preparation and premium coating systems is consistently outweighed by the long-term savings in maintenance and replacement costs." — Industrial Coating Journal

Conclusion

Corten steel continues to grow in popularity for its distinctive appearance and inherent durability. By understanding the appropriate surface preparation standards and coating systems, you can maximize both the functional performance and aesthetic appeal of this remarkable material.

Whether for interior or exterior applications, the combination of proper blast cleaning and Tnemec's specialized coating systems provides a reliable solution for protecting your Corten steel investments for years to come.

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL

Hot Dipped Galvanized Steel VS Zinc Rich Primer

IF STEEL IS GOING TO BE COATED, A ZINC-RICH...

Unlocking the Power of Zinc Primers in High...

Explore the transformative role of zinc primers...

Zinc rich primers in potable water tanks

Zinc Rich Primers In Potable Water Immersion