The Use of Crystalline Waterproofing Additives in Concrete

Multiple studies have shown the performance implications of using crystalline admixtures in concrete.

- High Performance Coatings

The Use of Crystalline Waterproofing Additives in Concrete

By: Cameron Walker

“Except for structural errors, about 90 percent of all building construction problems are associated with water in some way” (Moisture Migration in Buildings Publication #779, ASTM, 1982). There are a number of different systems and technologies used to help mitigate these problems. Some examples include moisture vapor mitigation, waterproofing, vapor proofing and drainage systems.

Classic positive side waterproofing systems are typically fluid applied or are constructed of thermoplastic materials. These systems are designed to form a continuous barrier to stop water from reaching the concrete. Technologies for these systems range from coal tar extended liquid or mastic applied materials to laminated plastics. Each of the systems have their own pros and cons in terms of cost, ease of application, performance, detail management, and extent of waterproofing properties.

The only technology that interacts directly with the concrete are crystalline waterproofing additives. These can be added to the concrete mixture or applied to the concrete surface after placement.

Crystalline waterproofing options are typically composed of cement, silica, and proprietary chemicals that react with water and hydroxides in the concrete to form crystalline structures. These crystalline structures fill and plug the concrete pores, cracks and voids to increase the overall density of the concrete. Due to the decreased porosity of the concrete, the concrete is more resistant to the passage of both physical and vapor forms of water.

Limitations of the crystalline waterproofing technology include the performance around construction joints, expansion joints, dynamic cracks, failing waterstops, areas of poor concrete consolidation, and around penetrations. In addition, intrinsic admixture crystalline waterproofing options may offer different results than those options that are topical applied at some point after concrete placement. When topically applied, the crystalline waterproofing materials should be allowed to reach its’ minimum 21-day cure with a subsequent abrasive blast to completely remove any remaining surface material. This is to ensure proper adhesion of any coatings applied to the concrete surface.

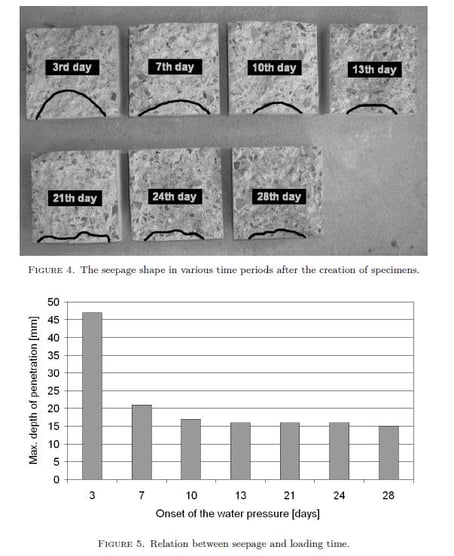

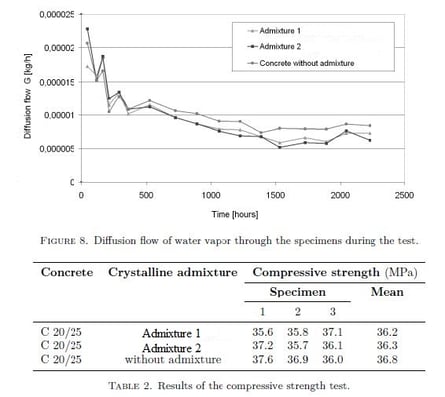

Multiple studies have shown the performance implications of using these crystalline admixtures in concrete. A study completed by Jiri and Eva at CTU in Prague looked at the performance implications of crystalline admixtures on selected properties of concrete (Pazderka & Hájková, 2016). The experiment evaluated the rate of waterproofing effect, impact to compressive strength, and the change in water vapor permeability. The results show that after approximately 12 days after placement, the admixtures reach their full waterproofing effect 1 and the water seepage distance decreased upwards to 76% from 3 days to 13 days (Figure 1). A minimal increase on the concrete’s final compressive strengths were noted while the admixtures caused a probable mild deceleration of the hardening of the concrete (Figure 2)2.

1 Water Pressure Test Per EN 12390-8

2 Strength test performed according to EN 12390-3

The experimental results, when using crystalline products, showed the ability for the crystalline admixtures to decrease the water vapour permeability by 16 to 20%3. (Pazderka & Hájková, 2016)

Just like all materials, performance of these products can vary significantly from one product to another. A critical review was published in Cement 2021 evaluating and reviewing a number of published papers throughout the industry. The results demonstrated similar overall trends throughout the industry (as discussed above) but the individual properties and results showed a wide range of performance capability (Tibbetts, Riding, & Gerraro, 2021). Formulation of each product is critical and testing should be utilized to confirm the conformance of the final concrete properties as required by the design.

Overall, crystalline waterproofing admixtures have shown that their use can impact the concretes properties to reduce both hydrostatic water pressure and vapour transmission effect. It is recommended to use crystalline waterproofing additives as a tool to reduce the risk of water passage through concrete while being used in conjunction with other positive side physical barriers as the use of the crystalline waterproofing additives are not a complete solution.

References

Pazderka, J., & Hájková, E. (2016). CRYSTALLINE ADMIXTURES AND THEIR EFFECT ON SELECTED PROPERTIES OF CONCRETE. Acta Polytechnica.

Tibbetts, C., Riding, K., & Gerraro, C. (2021, October 28). A critical review of the testing and benefits of permeability-reducing admixtures for use in concrete.

Figure 1: Insert from (Pazderka & Hájková, 2016)

_____________________________________________________

Figure 2: Insert from (Pazderka & Hájková, 2016)

_____________________________________________________

Figure 3: Important Industry Standards

___________________________________________

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL

Should I Repair or Replace Steel Members?

Steel structures form the backbone of our...

Overcoating Versus Complete Removal: Making the...

When faced with aging paint systems on steel...

No Need To Fear NSF-600!

Tnemec Company is well-prepared for the changes...