Tnemec Aerolon vs. Competitors: Which Safety Coating Is Best for Employee Touch Safety?

Explore the revolutionary properties of Tnemec Aerolon and how it measures up against other safety coatings in ensuring employee touch safety in high-temperature environments.

- Rick Gilbreath

Explore the revolutionary properties of Tnemec Aerolon and how it measures up against other safety coatings in ensuring employee touch safety in high-temperature environments.

Overview of Safety Coatings in Industrial Settings

Industrial environments frequently expose workers to hazardous conditions, including extreme temperatures that can make equipment surfaces dangerous to touch. Safety coatings are essential in these settings to protect employees from burns and other heat-related injuries. These coatings are designed not only to insulate and reduce surface temperatures but also to enhance durability and corrosion resistance of the equipment. The right choice of coating can significantly impact the well-being of employees and the longevity of machinery.

Navigating through the myriad of safety coatings available in the market can be daunting. Factors such as thermal insulation properties, ease of application, environmental resistance, and adherence to safety regulations need to be considered. Moreover, the coating's ability to maintain its protective qualities over time is crucial for ensuring ongoing employee safety and operational efficiency.

Key Features of Tnemec Aerolon for Employee Safety

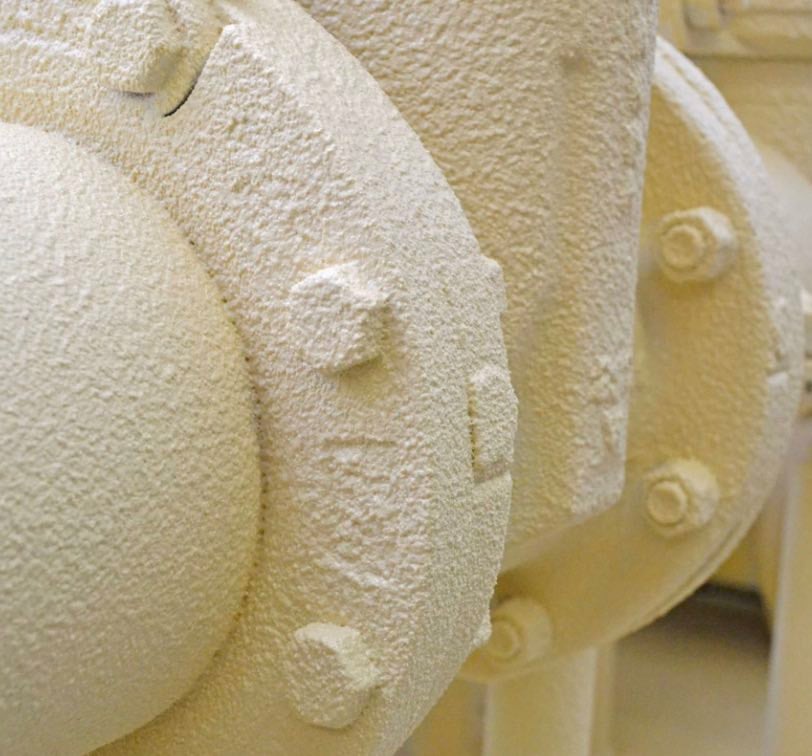

Tnemec Aerolon is a standout product in the realm of thermal insulating coatings. Its unique formulation includes a proprietary blend of insulating materials that contribute to its high-performance thermal barrier properties. Aerolon is specifically engineered to mitigate heat transfer and reduce surface temperatures, making it an excellent choice for ensuring the safety of employees who must interact with hot surfaces.

The key features of Tnemec Aerolon include excellent adhesion to a variety of substrates, resistance to corrosion and moisture, and durability in harsh industrial environments. Additionally, the product's quick-cure times and potential for thickness build-up without cracking or delamination are significant advantages. This ensures a longer lifespan and less frequent need for reapplication, making Aerolon a cost-effective investment for any facility prioritizing employee safety.

Comparing Tnemec Aerolon with Products

When evaluating Tnemec Aerolon against other safety coatings, several factors stand out. Aerolon's thermal insulating capabilities are often superior to many traditional coatings, offering better protection against heat. Its innovative use of aerogel technology aids in achieving a low thermal conductivity, which means it can maintain a safer surface temperature at a fraction of the thickness of other insulation coatings.

Other products may provide similar insulation effects but might not match Aerolon's ease of application or durability. Some coatings require multiple layers or have longer curing times, which can increase downtime and labor costs. Aerolon's ability to provide effective insulation with fewer layers and a faster return to service can be a significant advantage for many industrial facilities.

Case Studies: Real-World Applications and Results

Real-world applications of Tnemec Aerolon showcase its effectiveness in enhancing employee touch safety. For example, a chemical processing plant with high-temperature piping implemented Aerolon and reported a noticeable decrease in surface temperatures, which led to a reduced risk of burn injuries. The coating's long-term performance also meant fewer maintenance shutdowns, contributing to higher operational productivity.

Real-world applications of Tnemec Aerolon showcase its effectiveness in enhancing employee touch safety. For example, a chemical processing plant with high-temperature piping implemented Aerolon and reported a noticeable decrease in surface temperatures, which led to a reduced risk of burn injuries. The coating's long-term performance also meant fewer maintenance shutdowns, contributing to higher operational productivity.

Another case study in a power generation facility revealed that after applying Aerolon to their steam pipes, the surface temperature was lowered to a level that allowed for safe, incidental contact. This not only improved safety but also contributed to energy savings, as the insulating properties of the coating reduced heat loss from the system.

Choosing the Right Safety Coating: Factors to Consider

Selecting the right safety coating for employee touch safety is a complex decision that hinges on various factors. The operating temperature range, environmental conditions, surface material to be coated, and the specific safety requirements of the industry are all important considerations. Additionally, the ease of application, longevity of the coating, and overall cost, including maintenance and reapplication intervals, must be taken into account.

Facilities managers should also consider the technical support and documentation available from the manufacturer, such as performance data, safety certifications, and case studies. It's vital to choose a coating like Tnemec Aerolon that not only meets immediate safety needs but also aligns with long-term operational goals and sustainability practices.

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL

How Our Coatings Ensure Compliance for Potable...

Public Health is more important than ever, when...

Custom Coating Solutions for Your Water Tank

When you want nothing more than to ensure the...

NSF-Approved Coatings for Potable Water Tanks

Safe and Clean drinking water is crucial, but how...