Understanding Corrosion Under Insulation (CUI) and Coating Solutions

Corrosion under insulation represents one of the most challenging and costly maintenance issues in industrial facilities.

- High Performance Coatings

This hidden threat silently degrades piping and equipment, often remaining undetected until significant damage has occurred.

Understanding Corrosion Under Insulation (CUI) and Coatings Solutions:

Corrosion under insulation represents one of the most challenging and costly maintenance issues in industrial facilities. This hidden threat silently degrades piping and equipment, often remaining undetected until significant damage has occurred. For engineers and facility managers alike, understanding CUI mechanisms and implementing effective coating solutions is essential for asset integrity and operational safety.

What Is Corrosion Under Insulation?

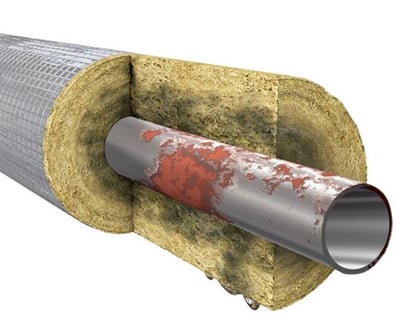

Corrosion under insulation occurs when moisture becomes trapped between insulation material and the metal surface it covers. Think of it like rust forming on your car's body panels underneath protective coverings where water gets trapped and can't evaporate. In industrial settings, this happens on insulated piping, pressure vessels, and equipment operating across various temperature ranges.

The insulation itself doesn't cause corrosion. Rather, it creates an environment where moisture can accumulate and remain in contact with the metal surface for extended periods. Unlike external corrosion that you can visually inspect, CUI develops in concealed areas, making it particularly insidious. By the time visible signs appear, substantial material loss may have already occurred.

Industry studies estimate that CUI accounts for approximately 40-60% of piping maintenance costs in refineries and chemical plants. Beyond direct repair costs, unplanned shutdowns can cost facilities hundreds of thousands of dollars per day in lost production.

Temperature Ranges and CUI Susceptibility

CUI doesn't occur uniformly across all operating conditions. The most critical temperature range is between -4°C and 175°C (25°F to 350°F). Within this band, moisture can exist in liquid form and accelerate corrosion reactions. The highest risk zone typically falls between 50°C and 150°C (120°F to 300°F), where cyclic wetting and drying creates particularly aggressive conditions.

Equipment operating below the dew point temperature presents another high-risk scenario. When surface temperatures drop below the dew point of the surrounding air, condensation forms directly on the metal surface beneath the insulation. Cryogenic systems present additional challenges, as ice formation can damage insulation and create pathways for moisture ingress during warming cycles.

Areas subject to temperature cycling face elevated risk as moisture repeatedly enters and concentrates during cool-down periods. Equipment at very high temperatures (above 175°C) generally experiences lower CUI rates because moisture evaporates quickly.

How Moisture Penetrates and Causes Damage

Several mechanisms allow moisture to reach metal surfaces. Damaged or improperly installed vapor barriers represent the most common entry point. Rain, condensation, washdown water, and process leaks all contribute moisture to the insulation system. Once inside, the insulation may retain moisture like a sponge, maintaining wet conditions against the metal surface.

When moisture contacts carbon steel surfaces, iron oxidation reactions begin—the iron combines with oxygen from the water to form rust. The confined environment under insulation concentrates corrosive species. Chloride ions from coastal atmospheres or cooling tower drift dramatically accelerate attack rates, with carbon steel experiencing corrosion rates potentially exceeding 1 millimeter per year in aggressive conditions.

Tnemec Series 971: A Proven CUI Solution

Tnemec Series 971 Aerolon is single component acrylic coating specifically engineered for CUI prevention. This high-performance system offers several distinct advantages for industrial applications:

Key Performance Features:

- Temperature resistance from -40°F to 325°F, covering the critical CUI temperature range

- Can be applied in a single coat at 50 mils dry film thickness in a single coat, reducing application time and labor costs

- Excellent adhesion to properly prepared and primed carbon steel

- Can be applied over zinc primer, to provide both barrier protection and zinc-rich corrosion inhibition

NACE SP0198 Standard and Tnemec Epoxy Systems

NACE SP0198 (now AMPP SP0198), titled "The Control of Corrosion Under Thermal Insulation and Fireproofing Materials—A Systems Approach," provides comprehensive guidance for preventing and managing CUI. This industry-recognized standard addresses coating selection, surface preparation, application, and inspection requirements specifically for CUI prevention.

Key Requirements of NACE SP0198:

The standard specifies that coating systems for CUI prevention should be selected based on:

- Maximum operating temperature of the substrate

- Cyclic temperature variations

- Environmental exposure conditions

- Expected service life

- Surface preparation limitations

For carbon steel in the critical CUI temperature range, NACE SP0198 recommends coating systems that include:

- Minimum surface preparation of SSPC-SP 10 (near-white blast) for new construction

- Minimum total dry film thickness of 10-16 mils

- Proven performance in CUI environments

Tnemec Epoxy Solutions Compliant with NACE SP0198:

Tnemec offers epoxy coating systems that meet or exceed NACE SP0198 requirements for CUI prevention:

Series 61 Epoxoline - A two-component polyamide epoxy coating offering exceptional performance for CUI applications:

- Temperature resistance to 200°F (93°C) for long-term exposure

- Outstanding water and chemical resistance

- Applied at 4-8 mils per coat

- Excellent adhesion and flexibility

- Proven track record in industrial CUI environments

Series 104 Epoxoline II - An advanced polyamide epoxy designed for severe service conditions:

- Temperature resistance to 250°F (121°C) continuous service

- Superior resistance to moisture, chemicals, and corrosive atmospheres

- Applied at 5-10 mils per coat

- Exceptional adhesion properties

- Ideal for both immersion and atmospheric exposure

Typical NACE-Compliant Systems Using Series 61 or 104:

System Option 1 (using Series 61):

- Surface preparation: SSPC-SP 10 (near-white blast) to 2-3 mil profile

- Primer: Series 90-97 (3-5 mils DFT) - zinc-rich primer providing galvanic protection

- Intermediate: Series 61 Epoxoline (6-8 mils DFT) - barrier coat

- Topcoat: Series 61 Epoxoline (4-6 mils DFT) - final moisture barrier

- Total System: 13-19 mils DFT

System Option 2 (using Series 104):

- Surface preparation: SSPC-SP 10 (near-white blast) to 2-3 mil profile

- Primer: Series 90-97 (3-5 mils DFT) - zinc-rich primer

- Intermediate: Series 104 Epoxoline II (8-10 mils DFT) - high-build barrier coat

- Topcoat: Series 104 Epoxoline II (4-6 mils DFT) - final protective layer

- Total System: 15-21 mils DFT

Both systems provide redundant protection layers meeting NACE SP0198 guidelines while leveraging the specific performance attributes of each coating type. Series 61 is often preferred for moderate temperature applications up to 200°F, while Series 104 is specified for higher temperature services up to 250°F or where enhanced chemical resistance is required.

Critical Application Considerations

Surface preparation ranks as the single most important factor in coating longevity. Achieving a clean, profiled surface through abrasive blasting removes mill scale, rust, and contaminants while creating a surface profile that promotes mechanical adhesion. Environmental conditions during application significantly affect coating cure—most systems require substrate temperatures above the dew point and within manufacturer-specified ranges.

Coating thickness control ensures adequate protection. Wet film thickness gauges during application and dry film thickness gauges after cure verify conformance to specifications. Holiday detection using appropriate voltage identifies pinholes and discontinuities before insulation installation.

Integrating Coatings with Insulation Design

An effective CUI prevention strategy extends beyond coatings to encompass the entire insulation system design. Vapor barrier jackets must be carefully selected, installed, and sealed to minimize moisture ingress. Weather barrier mastics, sealants, and tapes seal joints and penetrations.

Drainage provisions allow any moisture that does penetrate to escape rather than accumulating. Simple measures like slight slope to drain and weep holes at low points significantly reduce CUI risk. Removable insulation sections at vulnerable points facilitate periodic inspection.

Inspection and Maintenance Strategies

Even with robust coating and insulation systems, periodic inspection remains essential for managing CUI risk. A risk-based inspection approach prioritizes assets based on consequence of failure, susceptibility to CUI based on operating conditions, and time in service.

Advanced non-destructive examination techniques like pulsed eddy current, guided wave ultrasonics, and infrared thermography enable inspection through insulation without removal. Maintaining insulation system integrity through prompt repair of damaged jacketing and sealing penetrations extends the effective life of both insulation and underlying coatings.

Making the Business Case

Without adequate coating protection, CUI may necessitate pipe replacement after 10-15 years at costs including materials, labor, scaffolding, and production interruption—easily reaching hundreds of thousands of dollars for large circuits.

In contrast, applying a quality coating system at initial construction or during a planned turnaround might add 15-25% to the insulation installation cost but extend trouble-free service life to match or exceed the design life. The coating investment pays for itself many times over by eliminating premature replacements and unplanned maintenance events.

Conclusion

Corrosion under insulation presents complex challenges that require a systematic approach integrating material selection, coating application, insulation system design, and inspection planning. High-performance coating systems like Tnemec Series 971 Aerolon or multi-coat epoxy systems using Series 61 or Series 104 compliant with NACE SP0198 standards provide reliable long-term protection when properly selected and applied.

For engineers and facility managers, understanding CUI mechanisms and prevention strategies enables informed decision-making about asset protection investments. The modest incremental cost of quality coatings delivers substantial returns through extended asset life, reduced maintenance burden, improved safety, and operational reliability.

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL

No Need To Fear NSF-600!

Tnemec Company is well-prepared for the changes...

Understanding AAMA 2605 Standards for High...

AAMA 2605 is a stringent performance standard.

Unleashing Color Brilliance: Blending Pigment for...

Discover how blending pigments can transform the...