Secondary containment coating systems in the southwest

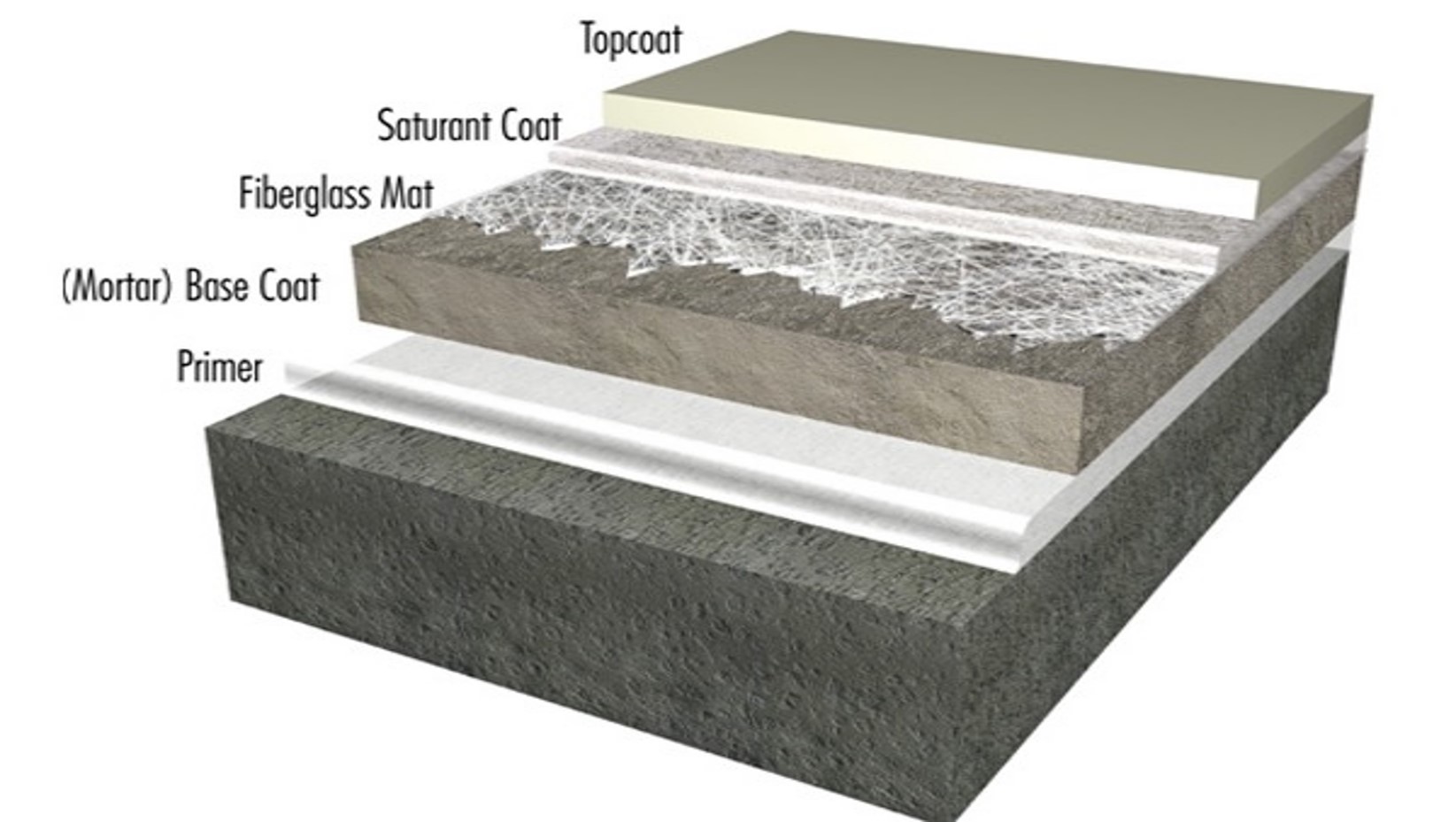

Fiber-reinforced secondary containment coating systems offer several advantages over traditional non-reinforced systems. Here are some reasons why fiber-reinforced secondary containment coating systems are often considered better.

PROJECT INFORMATION

Project Location

Southwest US

Here are some reasons why mortar/mat fiber-reinforced secondary containment coating systems (MRM) are often considered better:

- Enhanced Strength and Durability: The incorporation of fibers, such as glass or carbon, into the coating system significantly improves its mechanical properties. This reinforcement increases the system's resistance to cracking, impact, and abrasion, making it more durable and long-lasting.

- Crack Bridging Capability: Fiber reinforcement allows the coating to bridge small cracks that may develop due to temperature fluctuations or structural movement. This helps maintain the integrity of the containment system and prevents the leakage of hazardous materials.

- Improved Chemical Resistance: Some fiber materials are inherently resistant to a wide range of chemicals. When used in secondary containment coatings, these fibers enhance the system's ability to withstand exposure to corrosive substances, acids, and alkalis.

- Structural Integrity: Fiber-reinforced coatings can provide structural reinforcement to containment structures, such as concrete tanks or bunds. This added strength can help prevent structural failures and the subsequent release of hazardous materials.

- Reduced Maintenance Costs: The increased durability and crack resistance of fiber-reinforced coatings can lead to reduced maintenance requirements. This can result in cost savings over the life of the containment system.

- Longevity: Fiber-reinforced coatings tend to have a longer service life compared to non-reinforced coatings. This means that the containment system can continue to provide protection for an extended period without the need for frequent replacements or repairs.

- Compliance with Regulations: In many industries, there are strict regulations governing secondary containment systems to prevent environmental contamination and ensure safety. Fiber-reinforced coatings can help meet these regulatory requirements by providing a robust and reliable barrier.

- Versatility: Fiber-reinforced secondary containment coatings are adaptable and can be customized to meet the specific needs of different applications and environments. They can be applied to various substrates and can be tailored to resist particular chemicals or conditions.

- Improved Safety: The enhanced strength and durability of fiber-reinforced systems contribute to overall safety by reducing the risk of leaks and containment failures. This is especially critical when dealing with hazardous materials.

- Environmental Protection: By preventing the leakage of hazardous substances, fiber-reinforced secondary containment coatings contribute to environmental protection and help prevent contamination of soil, groundwater, and surface water.

Fiber-reinforced secondary containment coating systems offer superior strength, durability, and chemical resistance compared to non-reinforced systems. These qualities make them a preferred choice for industries where preventing the release of hazardous materials is of paramount importance. Contact us for more information.

Series 237SC Chembloc Secondary Containment Systems

Tucson Water 2013

City of Scottsdale Chaparral WTP 2013

Florence WTP 2014

Sedona Big Park WTP 2014

City or Phoenix Lone Butte WTP 2015

City of Goodyear WRF 2016

City of Phoenix Deer Valley WTP 2013-ongoing

Green Valley WTP 2017

City of Scottsdale Site 71 2018

City of Phoenix Airport 2018

City of Phoenix Val Vista WTP 2018

Town of Gilbert North WTP 2018

City of Goodyear 157th WRF Expansion 2019

Town of Gilbert NWTP 2020

Shea WTP 2020

Rogers Road WWTP 2022

Pecan WRP 2022

City of Mesa Warner Road Odor Control 2023

City of Scottsdale CAP Plant Water Campus 2023

Tucson Water Rogers Road WWTP 2024

Tucson Water Plant #9 2024

Series 239SC Chembloc Novolac Epoxy Secondary Containment Systems

City of Scottsdale North Indian Bend Wash 2013

City of Henderson Alfred Merritt Smith WTP 2017-2020

City of Glendale West Area WRF 2017

FMI Acid Plant 2018-2021

City of Mesa Vanguard Lift Station 2018

Palo Verde Generating Station 2013-2018

City of Phoenix Site 157 & 158 2018

City of Scottsdale Water Campus 2018

City of Phoenix Val Vista WTP 2018

City of Phoenix 24th St WTP 2018

City of Scottsdale Thomas Rd. Groundwater Facility 2020

FMI Globe 2022

Luke 303 WRF 2022

City of Phoenix 91st Ave WWTP 2022

ASR Well 7A 2023

South 32 Hermosa 2023

City of Scottsdale Well 54 2024

City of Scottsdale CAP Plant Water Campus Plant 3 Sodium Bisulfate Chemical Containment 2024

City of Phoenix 91st Ave 2024

City of Chandler OWRF IPS Odor Control 2024

City of Chandler WRF Improvements 2024

City of Mesa Signal Butte WWTP 2024

City of Mesa Superstition Vistas- Williams Field 2024

City of Phoenix Deer Valley WTP 2024

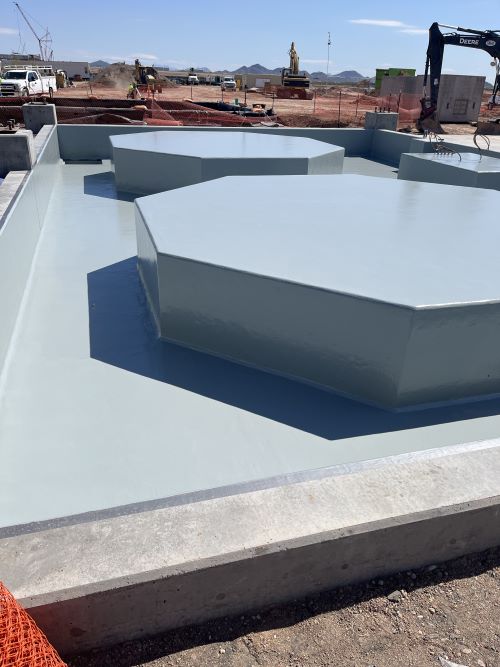

Series 252SC Chembloc Novolac Vinyl Ester Secondary Containment Systems

Fertizona Casa Grande 2014

Sedona WRF 2015

City of Phoenix Deer Valley 2015

CAP WTP Scottsdale 2018

City of Phoenix Cholla WTP 2020

City of Phoenix Pyramid Peak WTP 2020

City of Scottsdale CAP Plant Water Campus 2024

City of Mesa Signal Butte WWTP 2024

Check out these resources and projects related to secondary containment:

What Coatings Should Be Used In Secondary Containment

MORE HIGH PERFORMANCE COATINGS PROJECTS

Pyramid peak wtp secondary containment

The Pyramid Peak Water Treatment Plant in North Phoenix was expanded in 2021 and needed a secondary...

Market Type:

City of phoenix lift station 77

The City of Phoenix is rapidly expanding and is challenged by keeping up with enough water &...

Market Type:

Scottsdale Groundwater Treatment Facility

The Thomas Groundwater Treatment Facility (TGTF) was built in 2020 by Archer Western Construction....

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL