Brighton’s Wastewater Treatment Facility

When the clarifiers at the city of Brighton’s wastewater treatment facility started deteriorating plant engineers chose a proven Tnemec Protective Coating.

PROJECT INFORMATION

Project Location

Brighton, Colorado

Project Completion Date

December 2003

Owner

City of Brighton

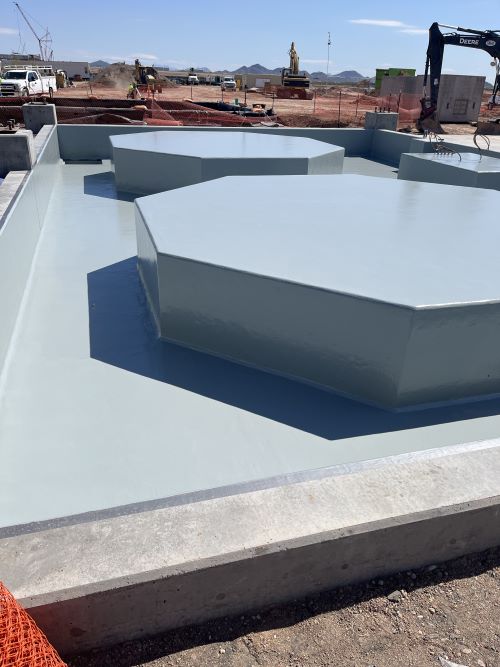

When the primary clarifiers at the city of Brighton’s wastewater treatment facility started deteriorating due to biogenic sulfide corrosion, plant engineers chose a proven protective coating system from Tnemec to prevent further damage. “It seems that between the waste influent and drought conditions, the plant’s owner noticed that the concrete paste was being attacked, causing accelerated deterioration of the clarifier launders,” according to Tnemec coating consultant Tom Quammen. “The wastewater manager for the plant contacted Tnemec, seeking assistance in selecting a coating system that would prevent further deterioration of the clarifier walls.” Quammen recommended a protective wastewater system formulated for high permeability resistance to sulfuric acid, H2S and other wastewater gases.

The project involved the outboard walls, floors and 18-inches up the inboard walls of the circular clarifiers, which were more than 60 feet in circumference. Surface preparation was in accordance with SSPC-SP13/NACE No. 6 Surface Preparation of Concrete, which included power washing and scraping to remove algae growth, followed by abrasive blast cleaning. That standard also includes a requirement for filling voids, bugholes and other cavities in the concrete to prevent entrapped air from being released into the protective coating.  The escaping air, which is described as bughole-induced outgassing, can be released into the protective coating during application, creating a discontinuous film for reduced barrier protection to the underlying substrate. The specification called for Series 218 MortarClad, an epoxy-modified cementitious resurfacer, to be trowel-applied to the clarifier’s outboard walls, floors and inside wall to achieve a smooth finish. The epoxy- polymer modification allows MortarClad to be applied as a thin-patch material, while increasing its density to make it less susceptible to outgassing when topcoated. Next, the contractor roller-applied two coats of Series 435 Perma-Glaze, a 100 percent solids polyamine epoxy coating, to an overall dry film thickness (DFT) of 30 mils. This abrasion-resistant lining provides extra protection in areas exposed to high hydrogen sulfide (H2S) levels, sealing the mortar resurfacer and creating a slicker surface resistant to slime growth. “Although the coating did not eliminate the algae growth, it made cleaning much easier and stopped the degrading of the concrete,” Quammen added.

The escaping air, which is described as bughole-induced outgassing, can be released into the protective coating during application, creating a discontinuous film for reduced barrier protection to the underlying substrate. The specification called for Series 218 MortarClad, an epoxy-modified cementitious resurfacer, to be trowel-applied to the clarifier’s outboard walls, floors and inside wall to achieve a smooth finish. The epoxy- polymer modification allows MortarClad to be applied as a thin-patch material, while increasing its density to make it less susceptible to outgassing when topcoated. Next, the contractor roller-applied two coats of Series 435 Perma-Glaze, a 100 percent solids polyamine epoxy coating, to an overall dry film thickness (DFT) of 30 mils. This abrasion-resistant lining provides extra protection in areas exposed to high hydrogen sulfide (H2S) levels, sealing the mortar resurfacer and creating a slicker surface resistant to slime growth. “Although the coating did not eliminate the algae growth, it made cleaning much easier and stopped the degrading of the concrete,” Quammen added.

The wastewater treatment plant in Brighton, Colorado, is scheduled to be decommissioned in 2031 when a new regional plant comes on-line. Until then, upgrades to the plant’s existing infrastructure are required to meet the needs of this rapidly growing community.

Reach out to High Performance Coatings to schedule a free site survey at your facility.

Check out these additional resources on wastewater and water treatment coatings

Severe Wastewater Testing for Coatings

Ductile Iron Surface Preparation

Engineers- Specifying High Performance Coatings

Coatings for Wastewater Facilities

Don't miss these wastewater and water treatment coating project profiles

Howard Berry Water Treatment Plant

MORE HIGH PERFORMANCE COATINGS PROJECTS

City of phoenix lift station 77

The City of Phoenix is rapidly expanding and is challenged by keeping up with enough water &...

Market Type:

Howard Berry Water Treatment Plant- Tank Lid...

The 27,000 s.f. post-tensioned tank lid at the Howard Berry Water Treatment Plant was...

Market Type:

Lamb Weston Potato Plant | High Performance...

The Lamb Weston frozen potato processing plant has been in operation since 1972 and employs around...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL