What are Static Dissipative Floor Coatings and Where are they used?

Electro Static Dissipative Floor Coatings are formulated to have electrical properties that allow the controlled dissipation of static charges.

- High Performance Coatings

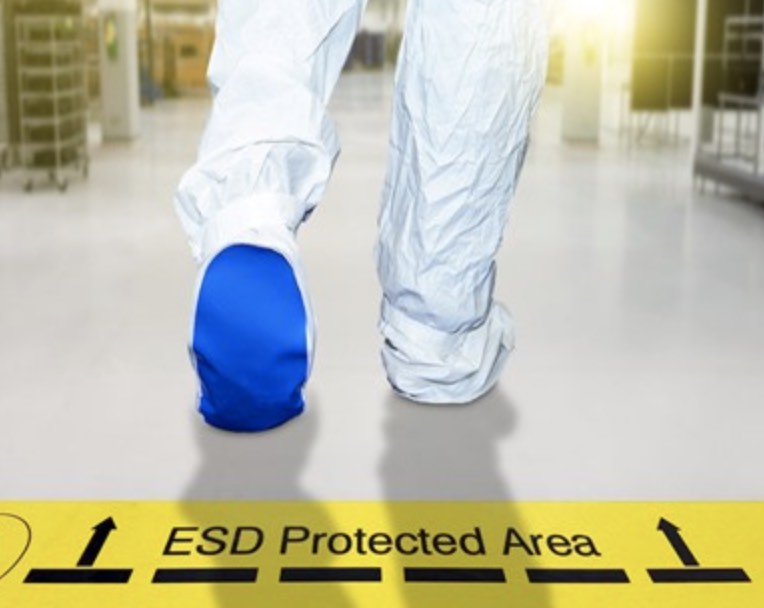

Static dissipative floor coatings are specialized coatings designed to control and manage static electricity in environments where electrostatic discharge (ESD) can pose a threat to sensitive equipment, materials, or personnel safety. These coatings are formulated to have electrical properties that allow the controlled dissipation of static charges, preventing the buildup of static electricity and reducing the risk of damaging ESD events.

Static dissipative floor coatings typically have a specific range of surface resistivity, measured in ohms per square. They are engineered to provide a middle ground between insulative materials (which prevent the flow of electricity) and conductive materials (which allow electricity to flow freely). This range of resistance helps in gradually releasing any static charge that might accumulate on the surface, rather than allowing sudden discharges that could damage electronic components or ignite flammable substances.

These coatings are commonly used in various industries, including:

1. Electronics Manufacturing: Facilities where electronic components are assembled or repaired are highly susceptible to ESD damage. Static dissipative floor coatings help protect sensitive components from electrostatic discharge.

2. Pharmaceutical and Chemical Industries: In environments where static electricity could ignite flammable materials or create hazards in sensitive chemical processes, these coatings are used to prevent ESD events.

3. Aerospace and Automotive: ESD can interfere with the production of aircraft and automotive components, affecting their electronic systems. Static dissipative coatings prevent such interference.

4. Cleanrooms: Cleanroom environments, which are highly controlled environments used in industries like semiconductor manufacturing and biotechnology, require static control to prevent contamination and ESD-related problems.

5. Server Rooms and Data Centers: In these facilities, static dissipative coatings help protect servers, networking equipment, and data storage devices from damage due to electrostatic discharge.

6. Healthcare: Some medical equipment and devices can be sensitive to ESD, making static dissipative coatings valuable in hospitals and medical laboratories.

7. Printing and Packaging: Static charges can cause defects in printing and packaging processes. Static dissipative coatings reduce the risk of these defects.

8. Explosives Manufacturing: In environments where explosive materials are handled, static control is critical to prevent accidental ignition.

Static dissipative coatings are part of a broader static control program that may include other measures such as proper grounding, antistatic footwear, and humidity control. They play a crucial role in creating safer and more reliable working environments in industries where static electricity can have detrimental effects.

Check out these other resources

Secondary Containment Coatings- What you need to know

Forklift Traffic on Warehouse Floors

Moisture Vapor Transmission Protection for Concrete Floors

Spalling Concrete and How to Fix It

Floor Coatings Are Not Easy to Specify

Selecting the Right Traffic Coating

Concrete Outgassing and How to Prevent It

Considerations Before Coating Concrete Floors

Selecting Coatings for Secondary Containment

Advantages of Polyurethane Cement Coatings

Exploring Decorative Resinous Flooring Options

UV Resistant Epoxy Floor Coatings

Don't miss these flooring project profiles

Secondary Containment Systems in the Southwest

Manufacturing Facility With Flair

Manufacturing Facility Drum Floors and Walls

Town of Gilbert NWTP Containment

What is Dissimilar Metal Corrosion?

What is Dissimilar Metal Corrosion, or Galvanic...

Enhancing Battery Manufacturing Facilities with...

The rapidly growing demand for batteries, driven...

What is ASTM B117 (Salt Fog) Testing and Why is...

What is ASTM B117 Salt Fog Testing?

ASTM B117...